Industry 4.0

Technological Revolution

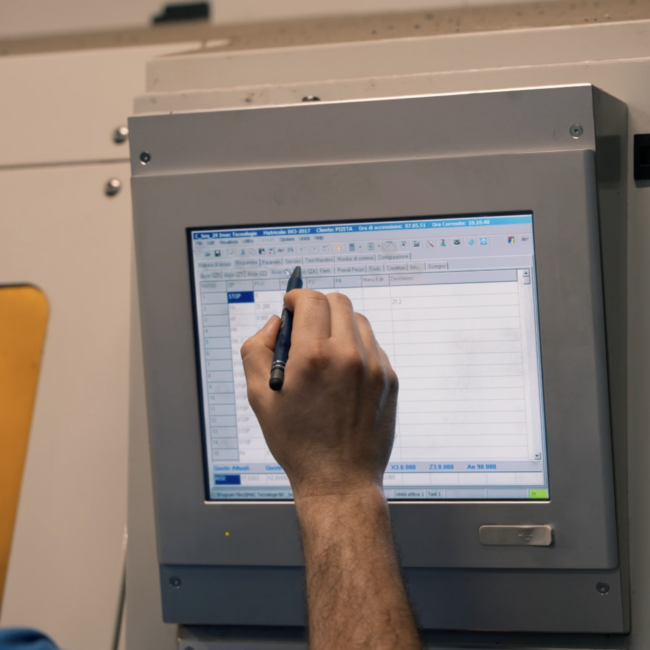

The implementation of new Industry 4.0-based machinery in our company represents a crucial step towards advanced and sustainable production. We have invested in new machinery and systems that allow us to connect, monitor and optimize every aspect of our production in real time.

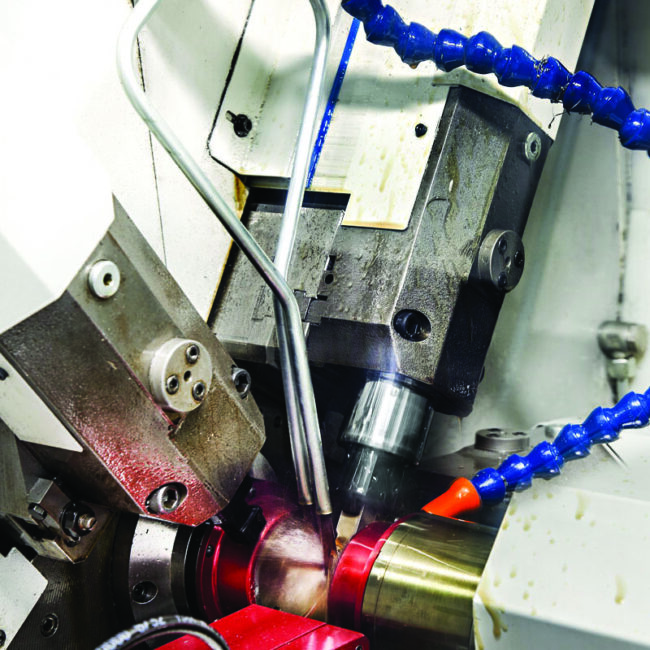

1. Advanced Automation:

Our new machinery is equipped with advanced automation systems that make production processes more efficient and accurate. The precision and consistency obtained through automation guarantee high quality products.

2. Increase of productivity:

Advanced automation has led to a remarkable increase in our productivity. The machines work more efficiently and with less margin for error, allowing us to achieve higher production than in the past.

3. Product customization:

The flexibility of the new machinery has allowed us to offer our customers highly customized solutions, without compromising production in significant volumes.

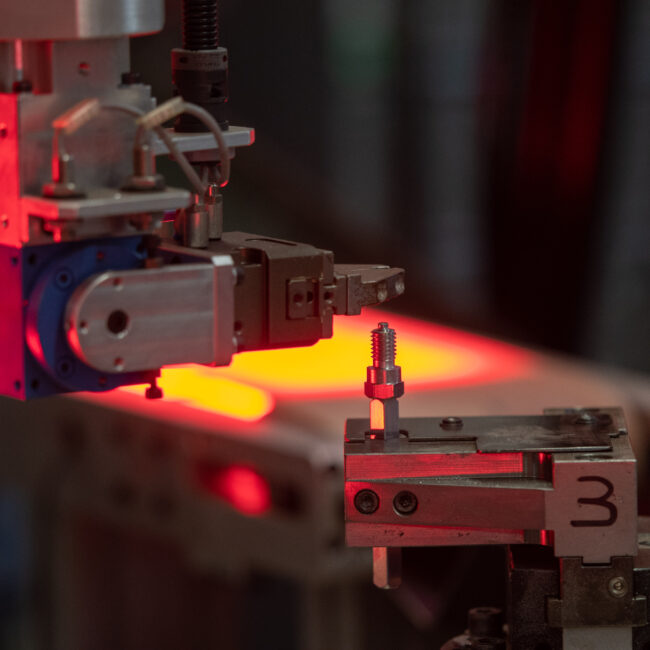

4. Reduction of operating costs:

Thanks to data analysis and predictive maintenance, we were able to reduce significantly operating costs. Identifying and fixing problems in advance led to significant savings.

5. Energy efficiency:

The new machinery is designed to use less energy, reducing costs and environmental impact. This helps us to ensure more sustainable operations.

6. Market Responsiveness:

Real-time connectivity has made us more responsive to market needs. We can make real time changes in processes and products , and guarantee quality and always manage to be aligned with customer requests.

Industry 4.0 represents a long-term commitment to the innovation and growth of our company. These technologies prepare us for a smarter and more competitive industrial future.